AAXAL Offshore Services

We provide cutting-edge and innovative services in structural integrity inspections using Advanced Non-Destructive Testing (ANDT) technologies for the detection of cracks, corrosion mapping & management, Corrosion Under Insulation (CUI) damage assessment, material loss and other failure mechanisms. Our technologies of choice are the Alternating Current Field Measurement (ACFM), Phased Array Ultrasonic Testing (PAUT), Pulsed Eddy Current Testing (PECT) and Long Range Ultrasonic Testing (LRUT). We have the capability to deliver these on surface to any operational height and under water to any operational depth.About AAXAL

AAXAL Offshore Services was established to provide cutting-edge and innovative services in

structural integrity inspections, Asset Integrity Management (AIM), Advanced Non-Destructive Testing

(ANDT), and offshore projects management.

Our mission is to provide innovative services of the highest quality that have a

positive impact on our client's bottom-line.

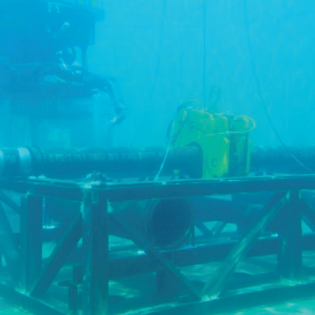

In our line of work, our solutions showcase the capability to conduct thorough inspections through coatings, rust, and grease, ensuring a comprehensive assessment. They excel in length and depth sizing, streamlining inspection processes. Notably, we offer a 'one-pass' inspection without the need for on-site calibration, reducing operational complexity. Minimizing dependence on operator interpretation, our solutions ensure precise results. Data is conveniently stored electronically, enhancing accessibility and record-keeping. We support remote deployment through divers, abseilers, or ROVs, proving the versatility and efficiency of what we do. Our solutions, with quick and easy deployment, adaptability to all sea states and visibility conditions, and suitability for high and low-temperature environments, represent the robust and versatile nature of our services. Automated deployment further enhances the adaptability of what we do.

Alternating Current Field Measurement for Surface Cracks

Alternating current field measurement (ACFM) is an electromagnetic technique for non-destructive testing detection and sizing of surface-breaking discontinuities.

We are proficient in ACFM due to its lower cleaning requirements and fewer false calls, which means inspections are significantly shorter, saving clients money.

Advantages of ACFM over other Techniques:

- Ability to inspect through coatings

- Length and Depth sizing

- A 'one-pass' inspection / no on-site calibration

- A high tolerance for lift-off

- Less reliance on an operator's interpretation

- Data stored electronically

- Remote deployment using divers, abseilers, or ROV

- Faster and easier to deploy

- Deployable in all sea states and visibility conditions

- Adaptable for automated deployment

- High & low temperature use

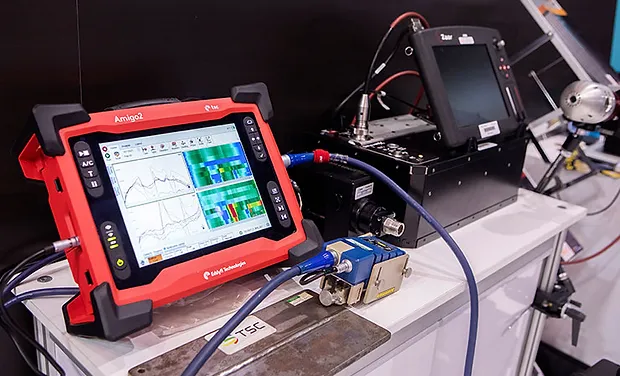

Pulsed Eddy Current & Eddy Current Array For Corrosion, Cracks and other structural defects

PEC is an electromagnetic inspection technique used to detect wall loss on ferromagnetic structures such as carbon steel and cast iron.

Advantages of PEC over other Techniques:

- Detecting and Sizing Cracks in Carbon Steel Welds

- Detecting Corrosion-Under-Insulation (CUI)

- Sizing cracks as deep as 10 mm for both length and position

- Allows simultaneously scanning the weld cap, toe area, and heat-affected zone

- Detects longitudinal and transverse cracks without surface preparation or paint removal

- Assessing Corrosion on Aluminium and Stainless Steel Tank Floors

- Detecting and Assessing Stress Corrosion Cracking in Base Metal

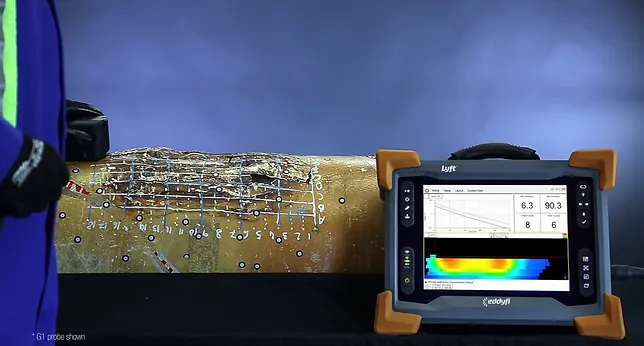

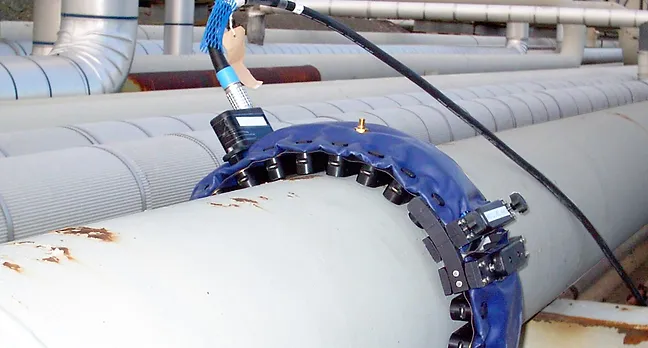

Long Range Ultrasonic Testing (LRUT) for Crack, Corrosion and other Defects on Pipelines and Tubulars

LRUT provides rapid screening for corrosion and erosion in pipelines. also known as guided wave ultrasonic testing, is a fast and cost-effective method for inspecting long lengths of pipes.

Advantages of LRUT over other techniques:

- Ability to inspect through coatings

- Inspection of buried pipelines without excavation

- Inspection of tubular columns without the need for a scaffold

- Ability to identify internal and external defects in the pipe under test

- Tens of meters can be screened from one location with internal and external defects detected

- Inspection rings of various diameters are easily positioned

- Topside and underwater applications

- High & low-temperature use

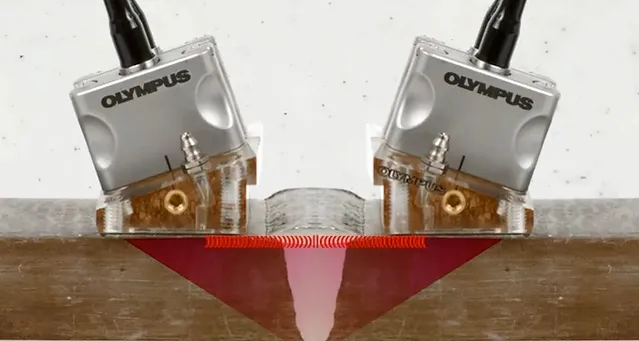

Phased Array UT (PAUT) For corrosion, cracks and other structural defects

Phase Array UT (PAUT) covers a range of ultrasonic inspection techniques using powered, mechanical scanners.

Although often used to describe corrosion mapping, AUT encompasses pulse-echo weld inspection, phased array, and Time Of Flight Diffraction.

Advantages of PAUT over other techniques:

- Automated inspection of tank walls for corrosion

- Thickness readings every 1mm

- Speed of up to 200 mm/s

- Works both in immersion and dry surfaces

- Dedicated software to API 653 standard

- Data stored electronically

- Saves cost on scaffolding/work platforms

- Fast and easy to deploy

Structural Inspections

- Surface and Underwater Structural Inspections

- Underwater Inspection in Lieu Dry-docking (UWILD)

- Port Facilities Inspection

- Thread Inspection

- Pipelines Inspection

- Rig Recertification

- Plant Inspection

- Tank Inspection

Offshore Projects Management

- Quality Assurance / Quality Control (QA/QC)

- Inspections Project Management

- Diving Projects Management

- Offshore Logistics Management

- Operator Training/Competence Assessment

- Setting up of RBI/RBM Systems

- Development of RBI/RBM Solutions

- Inspection/Maintenance Cost Analysis

- Failure Mode Mapping

- Wide Application (Structures, Plants and Pipelines)

Asset Integrity Management

- Abseiling

- Diving & Diverless Intervention

- Diving/Rope Access

- Remotely Operated Vehicles (ROV)

- Bespoke Testing & Inspection

- Pipeline Inspection

- Institutionalization of Structural Inspection Programmes

- Life Extension (LE) & Risk-Based Inspection (RBI)

- Engineering Asset Valuation